| 欢迎访问,冠华机械官方网站! | 服务电线: 0595-26983219 |

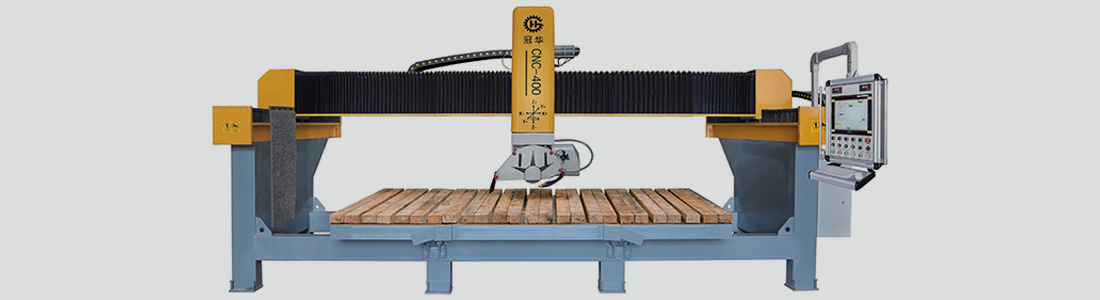

龙门式多片组合大切机

发布时间:2018/10/18 9:38:37

本机是在液压四柱式组合锯的基础上,通过优化改良而成的卧式四柱单臂大切,同时采用专利技术。边梁在切割时有液压锁紧装置,确保切割时整体机身不晃动,切割效率好,板材平整度高。

电路选用优质的电气元件及高精度的零配件,整机采用电脑全自动控制系统并配有微电脑编程控制和液晶显示屏控制,可精确设定各项切割参数。

主机身的纵向则由变频器和磁旋尺实现主动化精确分片,有效提高机台的自动化程度,大大降低生产成本。是一款在工人工资不断上涨,

电路选用优质的电气元件及高精度的零配件,整机采用电脑全自动控制系统并配有微电脑编程控制和液晶显示屏控制,可精确设定各项切割参数。

主机身的纵向则由变频器和磁旋尺实现主动化精确分片,有效提高机台的自动化程度,大大降低生产成本。是一款在工人工资不断上涨,

熟练工人日益紧缺的大环境下,取代普通单臂大切机的有效新机型。

The machine is on the basis of hydraulic four-post type combination saw, By optimizing the improvement of horizontal four

column single arm cut, At the same time using patented technology. You have the hydraulic locking device side beam in

cutting, Ensure that cutting the whole body shaking, Cutting efficiency is good, Plate flatness Circuit selects high quality

electrical components and high precision spare parts, The whole machine adopts the computer full automatic control system

with microcomputer programming control and LCD display control, All cutting parameters can be accurately set Main

longitudinal is consists of an inverter and magneticrotation ruler to realize precise subdivision, Effectively improve the

automation of themachine, Greatly reduce the production cost. Is a in the workers’ wages are rising, The circumstances of

increasingly shortage of skilled workers, instead of the ordinary single arm big effective new model of the cutting machine

分享到: