| 欢迎访问,冠华机械官方网站! | 服务电线: 0595-26983219 |

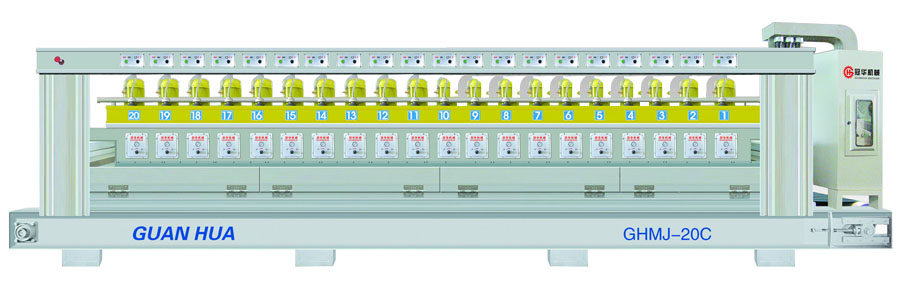

龙岗石条板磨机

发布时间:2018/10/18 10:09:32

该设备使用树脂磨盘,其磨盘重量轻,功耗小,单个磨头功率为7.5kw,其耗电量为传统连续磨机的1/3。操作控制系统采用PLC终端控制,通过液晶触摸屏进行参数设置,磨头升降及磨抛压力采用气动控制,

其压力大小需求在设定值内可调磨头横向磨抛速度及进板速度均采用变频调速并可在设定值范围内灵活设置。自动进板,磨头智能化识别板形状进行连续磨抛,

其压力大小需求在设定值内可调磨头横向磨抛速度及进板速度均采用变频调速并可在设定值范围内灵活设置。自动进板,磨头智能化识别板形状进行连续磨抛,

生产效率高,成本低,一套设备抵多台手扶磨或桥式半自动磨机生产效率,仅需人工1-2人。

The device uses light and low-power-consumption resin polishing disc With single polishing head consuming 7. 5KW power, its power

consumption is two quarters less than traditional continuous polisher. Controlling system adopts PLC terminal control for convenience of

setting parameters through LCD touch screen. The elevation of polishing head and grinding and polishing pressure, demand of which is

adjustable within set value, are pneumatically controlled. The machine is equipped with variable frequency adjustable speed system to

adjust speed of lateral grinding and plishing of plishing head and speed of transmitting slab and to adjust them flexibly within set

value, Slab is transmitted automatically Polishing head intelligently calculate the shape of slab and grind it continuously. Withe low cost and nd

high production efficiency, a set of this device equals several manual or semi-automaticbridge polishers and requires 1-2operators only

分享到:

- 上一篇:四柱栏杆仿形机

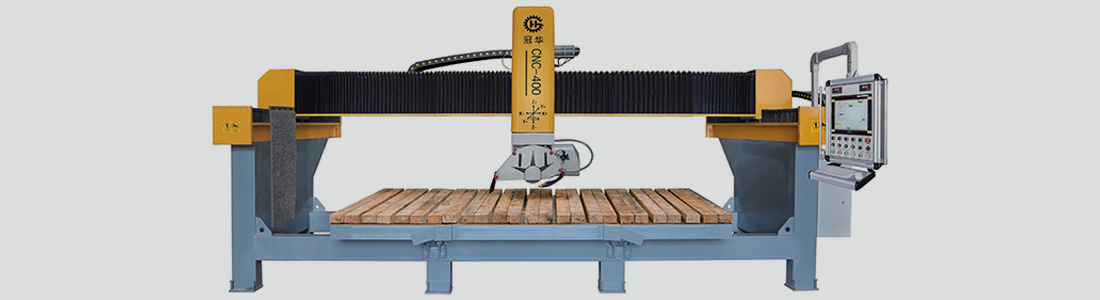

- 下一篇:龙门式多片组合大切机